Complete Skids for Vacuum Pumps

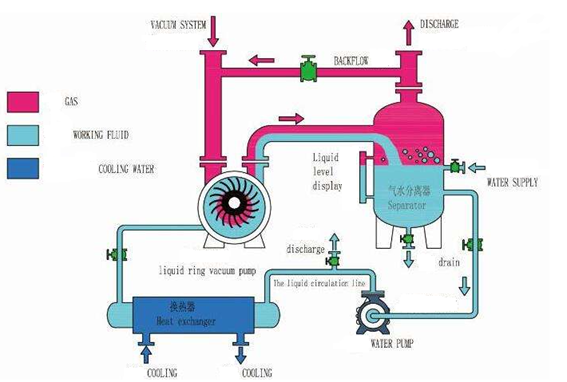

Liquid ring vacuum system with closed cycle.

Technical Description

Closed-loop liquid ring vacuum system

1. Normal operation of the water ring vacuum pump requires a lot of working fluid. Based on different pump sizes, the working fluid consumption per hour is from 0.12m3/h to 50m3/h. If we only rely on continuous external water supply, the accumulated water consumption every year will be very large. The application of water ring pump closed cycle vacuum system can avoid waste of working fluid.

2. In the chemical industry, there are toxic and harmful liquids, and some flammable and explosive gases, the circulating fluid cannot communicate with the outside world. To avoid workplace pollution, the closed-loop vacuum system adopting stainless steel flow parts and mechanical seal can solve these problems.

3. When water quality cannot be guaranteed, serious scaling may occur after a very short period of time. And this may affect the normal operation of the pump. We can then add a softening tank before the pump, consisting of equipment similar to a closed loop unit to monitor the level with constant addition of soft water. By doing this we can guarantee the proper functioning of the system.

4. To make the system run smoothly and reliably, the pump group can be set to one opening and one closing (for priming), or multiple opening and multiple closing (for priming). When starting the system operation, we open several pumps at the same time to meet the system process requirements in a short time. After the feedback signal, an electronically or remotely controlled spare pump shuts down, leaving only one or several to maintain the pump to maintain the system vacuum, reducing the power of the entire system, shortening the process time and improving automation.

5. Large equipment of complete sets of water ring vacuum pump systems can be used in gas drainage, pressure adsorption, transportation filtration and other industries. Our company has designed a complete set of mobile gas pumping stations and equipped with a sound monitoring and control system, all supporting 2BE products to ensure reliable unit operation.

6. When evacuating closed containers such as drying systems, the required vacuum of the system is much higher than the water ring pump, so we can connect the Roots pump to become a Roots – water ring vacuum system To improve suction capacity, end vacuum to meet requirements. The ultimate pressure of three Roots units plus water ring vacuum pumps can be about 0.5Pa.

7. The application of high pressure water ring compressor should be added after a back separator, the container is a category of pressure vessel, playing the role of gas-water separation, voltage transmission, and can provide circulating fluid. This type of compressor can compress hydrogen, acetylene and other gases generated by the chlor-alkali industry. Generally with heat exchangers, centrifugal pumps and other accessories, all units only need to remain at the interface, with user-friendly installation and commissioning.

SKID system operating diagram

Contact

Request your quote

Send a message to our team and we will get back to you!